A market leader in 12kV switchgear, the Eclipse is designed to provide a lifetime of unrivalled service, bringing together one of the most advanced operating mechanisms available on the market today – the award winning magnetic actuator technology – with vacuum interruption and the simplicity of air insulation in a compact, fixed pattern design.

Appreciated throughout the distribution network and across every business sector, the Eclipse currently holds a dominant market position for indoor 12kV switchgear.

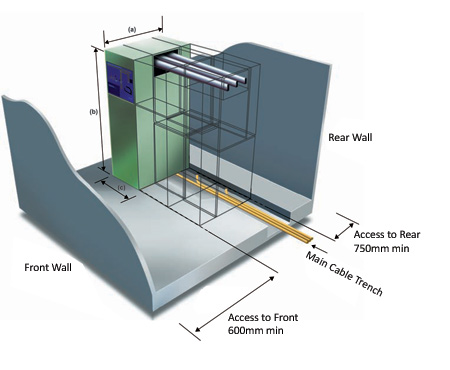

Dimension (In mm)

- Dimensions for a standard Eclipse feeder/incomer panel;

(a) 1162 (b) 2165 (c) 500

- Dimensions for a standard

Bus-section panel;

(a) 1162 (b) 2165 (c) 1000

- Dimensions for a Busbar earthing switch; (c) 325

- Dimensions for a single panel with Busbar VT; (b) 2500

- Dimensions for top entry cable; One cable per phase - (a) 1482

- Three cables per phase - (a) 1812

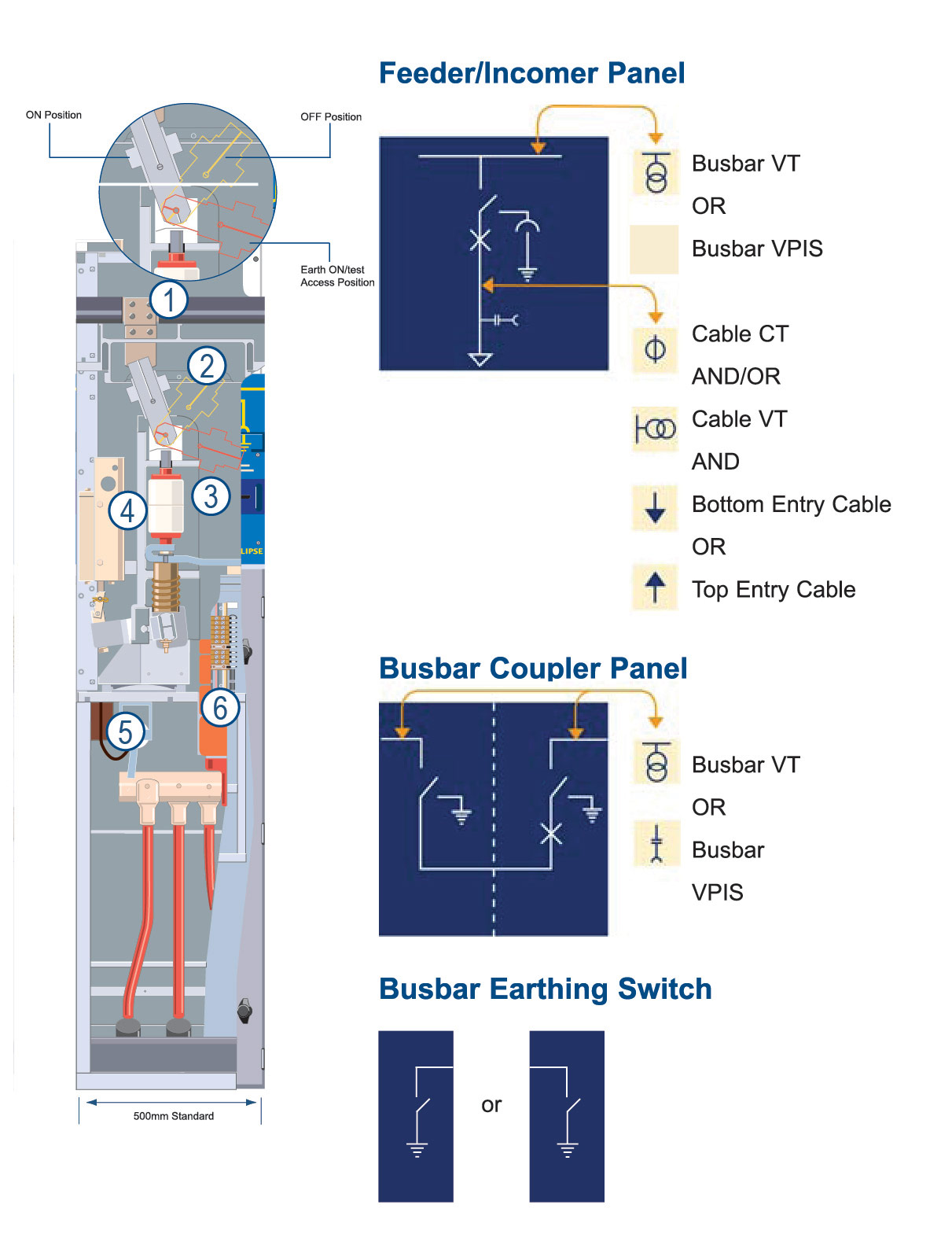

Eclipse Engineering Detail

- Sleeved busbars constructed from hard drawn, high

conductivity copper, and vermin proof covered joints, 1

with normal current ratings up to 2000A. The busbar

arrangement permits future expansion, at either end of 2

the switchboard.

- Fully interlocked, manually operated 3-position disconnector including circuit earth and front panel cable

test access. The disconnector can be secured and 4

padlocked in all three positions: ‘on’, ‘off’ and ‘earth on/ test’, with its status indicated by animated front panel mimics.

- A single moulding supports the three phase vacuum

interrupter assembly, magnetic actuator mechanism and 6

one-piece drive beam. 5

- The patented single coil magnetic actuator mechanism is based on a solenoid plunger, held in the tripped or closed position by permanent magnets.

- Three phase cast resin voltage transformer, with manually operated off-load disconnector on the primary circuit.

- Generous CT accommodation enables complex protection schemes to be catered for in a single panel, whilst still allowing for a metering provision. The CT designs are rated in keeping with the short time withstand level of the equipment and comply with IEC 60044-1.

Unique Front Access Cable Testing Option:

- Avoids any contact with Live cables or busbars.

- Eliminates the need for Opening of rear covers to access live cables.

- Provides secure & mechanically interlocked front access contacts points to connect cable test equipment.

- Colour coded and suitably

labelled copper contacts

eliminates risk of improper

connections during testing

live cables.

| Rated Normal Current |

A |

630/1250 |

| Rated Voltage |

kV |

12 |

| Rated Frequency |

Hz |

50 |

| Rated BIL |

pk kV |

75 |

| Rated Power Frequency Withstand |

kV 1min |

28 |

| Rated Short-Time Withstand Current |

kArms 3secs |

25 |

| Rated Peak Making Current |

pk kA |

50/62.5 |

| Internal Arc Compliance |

kA 1sec |

25 |

| Rated Short Circuit Breaking Current |

kA |

20/25 |

| Degree of Protection * |

|

IP4X |

*Higher Ratings available on request

| Auxiliary Operating Supply |

125/110/48/30V dc |

| Typical Weight Range |

500 - 650kg |

| Busbars |

1250A |

Normal Service Conditions:

| Ambient air temperature |

-5ºC to +55ºC |

| Relative humidity |

<95% |

| Altitude |

<1000m |

Standards:

- IEC 62271-200, IEC 62271-100, IEC62271-102, IEC 62271-1

- ENA TS 41-36

|

|

|

|

| Switching Station |

Transport Applications |

Seconday Substation applications |

MOD |

| |

|

|

|

|

|

|

|

| Industrial |

Hospitals |

Education |

Commercial |

| |

|

|

|

|

| Utilities |